Utility Boiler

Toolfab an ISO 9001 : 2008 Certified company manufactures Package Utility Boilers of various range in capacity upto 20000 Kg/Hr with superior quality, optimized design, High performance, competitive cost and prompt delivery and commissioning support.

-

Key Efficiency Features

Our manufacturing facility features of 3 massive bays with a well defined production setup. The design of stage combustion which results in high degree of swirl induced in the primary and secondary air streams which enables optimal control of flame characteristics & high thermal efficiency of 80%.

- 1

- 2

Boiler Construction & Capacity

Our Solid Fuel Packaged Boilers are manufactured in accordance with the Boiler regulations and standards given by IBR.

G IBR 1950

Sufficient Expansion compensation is provided in the furnace to safeguard towards thermal stresses.

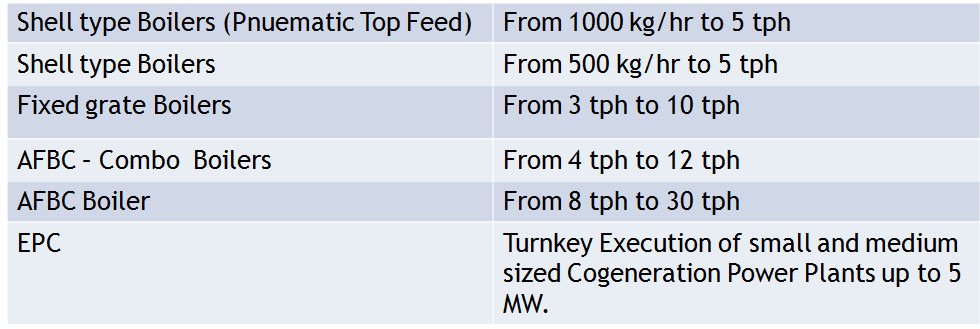

Our Boilers are manufactured over a wide standard range.

Salient Features

- Factory Assembled – IBR approved horizontal package Boiler.

- Maximum Efficiency – Minimum Heat Losses.

- 3 Pass Heat Transfer – Maximum heat recovery.

- Large Steam Release Surface.

- Quick and easy De-Ashing.

- Feed pump with Auto level controller.

- Steam pressure control with Pressure switch Interlock.

- Pre-wired/tested Electrical Control Panel with accessories.

- High Quality components like forged steel valves, pumps, pipes etc.

Manufacturing Features

- Built-up with boiler quality steel.

- High quality Tube

- Plate forming.

- High quality, SMAW/TIG welding.

- NDT, SR, Hydro Test conducted.

Quality Facility

- Toolfab’s Boiler Quality is powered by

- ISO 9001 : 2008 Certification for Quality Systems.

- ISO 3834: Part II Certification for Weld Shop approval.

- 100% Certified welders for IBR Standard.

- In House NDT Level II Technicians and NDT Equipments.

- Testing Methods: Visual, Dimensional, Radiographic, MPE.

- High quality Stage wise Inspection.

Customer Portfolio

-

TFB001 Ganesa Modern Rice Mill - Attur, Tamilnadu

Click Here for Boiler_Range -

TFB002 DACK vessels - Bangalore, Karnataka

Click Here for Boiler_Range -

TFB003 Balaji Modern Rice Mill - Kallakuruchi, Tamilnadu

Click Here for Boiler_Range -

TFB004 Venkateswara MRM - Manapparai, Tamilnadu

Click Here for Boiler_Range -

TFB005 Shanmuga Modern Rice Mill - Attur,Tamilnadu

Click Here for Boiler_Range -

TFB006 Manigandan MRM - Chengalpattu,Tamilnadu

Click Here for Boiler_Range -

TFB007 Elumalayan Modern Rice Mill - Pattukottai, Tamilnadu

Click Here for Boiler_Range -

TFB008 Super sizing - Avnashi, Tamilnadu

Click Here for Boiler_Range -

TFB009 Senthil murugan MRM - Thirukovillur,Tamilnadu

Click Here for Boiler_Range -

TFB009 Senthil murugan MRM - Thirukovillur,Tamilnadu

Click Here for Boiler_Range -

TFB010 VJS ENERGY - TRICHY, Tamilnadu

Click Here for Boiler_Range -

TFB011 MRC Mills Pvt. Ltd - Karur, Tamilnadu

Click Here for Boiler_Range -

TFB012 Stallion garments - Thiruppur, Tamilnadu

Click Here for Boiler_Range -

TFB013 GEETECH - TRICHY, Tamilnadu

Click Here for Boiler_Range